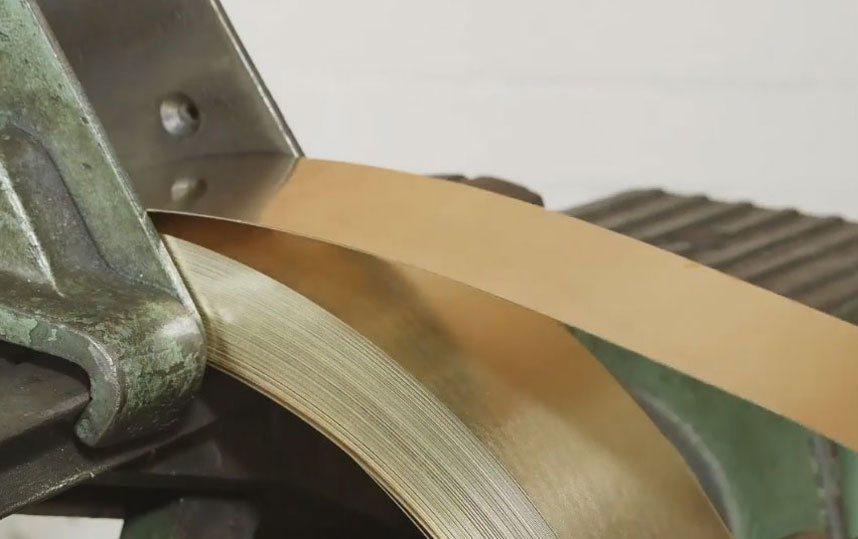

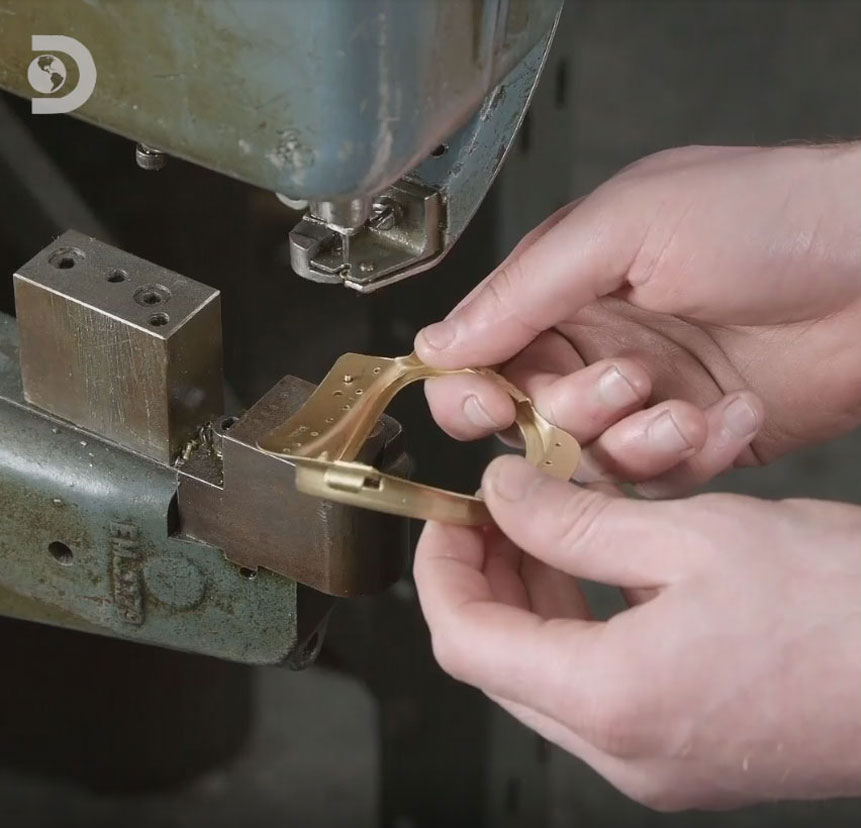

Production on the Halcyon motorcycle goggles begins with a coil feeder, feeding the strip of soft brass into a press that stamps out a series of flat blanks. The press also punches two guide holes that will be used to position the blanks in the next stage of production where the left and right eyepieces are formed. A further press then refines these blanks, after which the centre hole is stamped out. Holes to stitch the leather face-pad to the eyepiece are then punched out.

Old power press machinery

A different press then pieces stitching holes that run along the side of the frame.

Because of the machine’s age, the distance between the holes has become slightly uneven.

Next, the motorcycle goggles nose bridge bracket is placed onto a rivets shaft. After positioning an eyepiece on top, the two are riveted together. Before joining the left and right eyepiece, each one is given a thorough polishing. This is a two-step process starting with an operation called skirfing which prepares the surface, followed by polishing a special compound.

The side lenses are fitted at a 45-degree angle, so to marry each to its front lens at a 22-degree angle is ground on the adjourning edges of both. A slight burr left from the grinding process is removed, these lenses are made from shatterproof laminate for safety reasons.

A piece of painted brass will serve as the lens frame, this has been kneeled to soften it in preparation for the next phase which first sees a temporary steel rod inserted. The assembly is then placed in a clamp to fit a temporary brass cleat.

Creating the 45-degree angle on the lenses

A purpose-built hand press is then used to bend a section of the frame at 45 degrees after removing the support rod, glue is supplied to the front lens. And after fitting the side lens a permanent brass cleat is used to secure the frame.

Lamb-Nappa leather face-pad

The Halcyon motorcycle goggle eyepieces are now ready for the next stage of production. This will see them being attached to a leather face pad, which is made from lamb nappa leather. And is produced by stamping out the acquired pieces using a dye and press. The top and bottom layers of the face pad are then stitched together. The gap between each stitch is 1 ½ mm, this ensures that the join is both secure and the stitching doesn’t over-perforate the leather.

Next, padding is sewn into place using a specialized machine and an overlocking stitch. This is a difficult operation and it takes up to 7 months of training to become truly proficient at it. Before sewing the face pad to the eyepieces, the layers of the nose guard are glued together. After letting the glue cure for a few hours, the eyepieces are then stitched by hand to the face pad.

How motorcycle goggles are made.

The motorcycle goggles are now nearly complete. The frames and lenses are fitted into channels of the eyepieces and then finally the headband is attached using clips, which also locks the lenses in place. And with that, it’s chocks away and on your bike!

First, a special thanks to Discovery Channel UK for this ‘How it’s Made’ production. Furthermore a thanks for Halcyon Classic Parts (www.Classicpartsltd.com).

Find classic goggles on

| WHERE TO BUY – FIND ONLINE | ||

| Classic Motorcycle Goggles | ||

| Amazon | Price: £68.95 | Check out the Amazon marketplace. |

| Classicpartsltd | Price: £71.95 | Halcyon manufacturers. |